Freelancer tips

Freelancer tips Process Operations Diagram: What It Is and How to Make One

The process operations diagram helps organize tasks, improve productivity, and support better decision-making. Learn how to create one here.

The Theory of Constraints (TOC) is a methodology that helps uncover which part of a process slows the final outcome. Its goal is to identify the main bottleneck and direct actions there to improve it so everything moves forward with less effort.

The theory was proposed by Eliyahu M. Goldratt in the 1980s. His novel The Goal, set in a manufacturing plant, helped popularize the approach.

Today, it has spread to multiple areas (operations, services, projects, freelance work). If you want to apply it, stick around and discover what it is, its types, the five focusing steps, and how to leverage it.

The Theory of Constraints consists of finding the element that reduces a system’s performance and focusing improvement on overcoming that barrier.

TOC (Theory of Constraints) posits that every system runs at the pace of its weakest point (constraints or bottlenecks). Even if several parts work well, that limitation determines how far the whole can progress.

That’s why the approach doesn’t try to improve everything at once. Its priority is to strengthen the critical point, because solving it lifts overall performance without unnecessary investments.

In TOC, a constraint can appear at any stage of a project, process, or operation. And it’s not always a technical problem—it can also arise from the market, internal rules, or the supply chain.

With that in mind, here are the main types of constraints:

Physical constraints. They arise when a resource doesn’t have enough capacity, directly affecting production or process pace. It could be a slow machine, little space, lack of staff, or limited technology.

Market constraints. The system produces well, but the market doesn’t absorb enough. These appear in saturated contexts, shifting preferences, or intense competition.

Policy or rules constraints. Limits created by internal decisions, including rigid norms, inherited processes, or bureaucracy that delays key tasks.

Supply or logistics constraints. Flow is halted by factors external to the process, such as slow suppliers, transport delays, or lack of essential materials.

Understanding where the blockage originates lets you direct improvement at the right point.

In some cases, the brake doesn’t come from the process itself, but from how the organization works. Things like lack of team experience, habits that delay decision-making, or internal dynamics make it harder to move quickly.

TOC proposes five focusing steps to improve any process systematically:

Identify the constraint.

Exploit the constraint.

Subordinate everything else to the constraint.

Elevate the constraint.

Review and repeat the cycle.

Here’s what to do in each step:

First, detect which stage, resource, task, or person is stopping the flow. In the freelance space, for instance, it could be time management if hours aren’t enough to move forward.

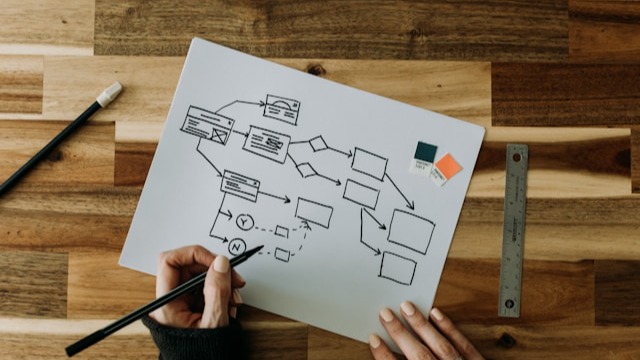

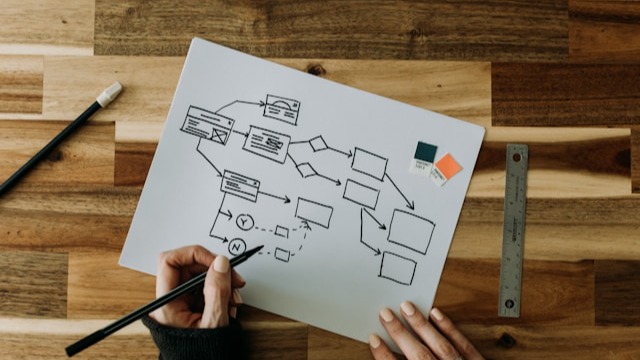

To be sure, it’s helpful to use visual tools like a flowchart that helps locate where the bottleneck appears.

The idea is to reduce idle time, eliminate irrelevant tasks, and prioritize flow through the limited point.

The rest of the system must adjust to the pace of that weak stage. This includes offloading work, reorganizing tasks, and avoiding producing more than the constraint can process.

If the limitation persists, it’s time to increase its capacity. This may involve investing in tools, improving skills, or reorganizing project operations.

Once you overcome a constraint, another will likely appear. That’s why TOC is a continuous improvement process that loops back to the start to sustain performance.

Even so, it doesn’t hurt to use techniques like deep work to maintain focus and avoid new interruptions to your workflow.

This section compiles cases to help you understand what the Theory of Constraints is with simple, applicable examples.

TOC examples:

Factory. A production line has a machine that runs more slowly than the rest, delaying the entire process.

The theory prioritizes its use, organizes flow around that stage, and eliminates tasks that distract it.

Project or development team. In a software team, testing (QA) can become the bottleneck when validating each task takes longer than coding it.

TOC improves the flow, automates tests when possible, and limits work in progress to avoid overwhelming that stage.

Creative agency. In an agency, many ideas depend on a creative director’s time. If that person receives too many requests, the team stalls.

With the theory, you protect that person’s workload, set priorities, and adjust the flow—so a single stage doesn’t limit all the work.

Classic example from The Goal. The book describes a plant where certain resources work more slowly than others.

By redesigning planning based on those limited points, the company reduces inventory, speeds up deliveries, and improves financial results.

It’s one of the most cited TOC cases.

Applying TOC relies on three fundamental tools:

Drum-Buffer-Rope (DBR). A way to organize work around the bottleneck, focused on production flow:

The drum sets the system’s pace.

The buffer creates a small cushion to avoid delays.

The rope controls how much work enters so the limited stage isn’t overloaded.

Critical Chain Project Management. This tool applies TOC to projects. Instead of worrying about each task separately, it prioritizes the tasks that actually define the project’s finish date. It uses time buffers to protect that sequence and avoid unnecessary delays.

Thinking Processes. Visual tools to understand complex problems. They help identify what causes the limitation, what effects it generates, and what change would create a real improvement.

That’s why the Thinking Processes often use decision trees to compare options and choose the most effective.

In short, these key concepts let you control flow, manage projects, and make strategic decisions with TOC.

TOC promises dramatic results by focusing energy on a single leverage point. But it also has challenges you should consider before implementing it:

Direct focus. Resources are concentrated only on the bottleneck, maximizing system performance without scatter.

Improvement without big spending. Many solutions come from adjusting processes, priorities, or internal rules, so meaningful progress is possible without investing in more resources.

Versatile. It can be applied in factories, projects, logistics, services, or highly digital work, as it adapts well to different types of processes.

There isn’t always a single constraint. Sometimes multiple bottlenecks appear at once or shift quickly, complicating a single line of improvement.

It requires reliable information. Finding the true constraint demands a broad understanding of the process. Without clear data or cross-team collaboration, analysis becomes imprecise.

It may face internal resistance. Some organizations prefer to optimize each area separately. That clashes with TOC, which prioritizes global performance over local optimization.

This shows TOC isn’t a magic solution, but it is a practical way to understand how work flows and where to focus efforts.

TOC adapts well to almost any environment. It works in companies with teams and formal processes, and also for successful freelancers or remote teams.

With this approach, you can better choose which projects to prioritize, which tasks to delegate, and how to organize your day to maximize hourly earnings.

The steps to apply it are simple:

Analyze how your work flows. Observe the full path of a task—from the moment a request arrives to delivery. This will help you understand which stages have more work than others.

Locate the limiting point. Certain tasks pile up or cause delays—for example, reviews, approvals, or billing processes.

Put the five focusing steps into practice. Adjust how you work to better exploit that limited point and align the rest of the process to its pace. Then, bolster its capacity if it still slows progress.

If there are many interconnected tasks, don’t hesitate to create a timeline to see what depends on what.

The Theory of Constraints explains that every process has a point that slows performance.

When you identify and improve it, the entire system moves faster and with less effort.

Its principles also apply to freelancers and small businesses working with clients in different currencies.

It can even help you see what’s limiting your income and make your business model more stable. Combined with tools like DolarApp, you can create a more orderly flow and generate more value per hour worked.

Why?

Because DolarApp is a practical app for receiving, sending, or exchanging digital dollars/euros at a transparent, fair rate. Used together, both are practical solutions to improve your day-to-day.

It’s a method that helps improve a business or process by identifying the part that most slows it down. It directs improvement toward that point so the system moves with greater flow and better results.

Its goal is to improve the system’s overall performance by focusing efforts on the primary constraint. By optimizing that critical point, the whole system works better without optimizing every area at once.

First, find the constraint; then exploit it; subordinate everything to it; elevate its capacity when necessary; and fifth, repeat the cycle to keep improving.

In a factory, a slow machine can hold up all production. TOC proposes making better use of it and adjusting flow around that stage before adding more resources.

Sources:

The world has borders. Your finances don’t have to.

Freelancer tips

Freelancer tips The process operations diagram helps organize tasks, improve productivity, and support better decision-making. Learn how to create one here.

Freelancer tips

Freelancer tips A business brings new challenges and decisions as it scales. Learn the stages of business growth and identify which stage you’re in.

Freelancer tips

Freelancer tips A well-written privacy policy makes users trust your site more. Here are the necessary elements and a practical example to create one.