Freelancer tips

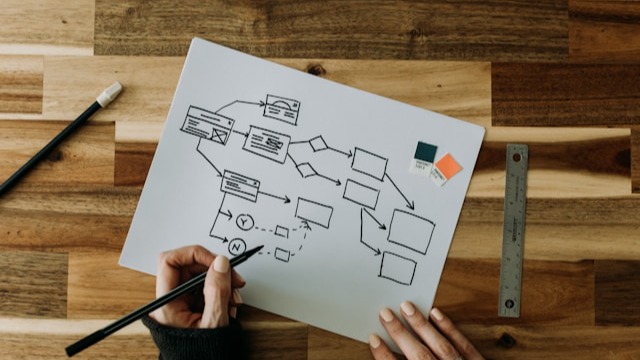

Freelancer tips Diagrama de Fluxo de Processos: o que é e como criar um

O diagrama de fluxo de processos ajuda a organizar tarefas, aumentar a produtividade e apoiar uma tomada de decisão mais eficiente. Saiba como criar um aqui.

Six Sigma is a continuous improvement management model that seeks to reduce errors and variation in processes. It was introduced in 1986 by Bill Smith, a Motorola engineer, with the aim of improving quality in electronic manufacturing.

Today, it’s a global standard for growing and staying competitive in the business environment. If you want to know what Sigma is and why it’s applied by organizations of all sizes, this post tells you all about it.

It’s a continuous improvement management method designed to minimize failures and variation within a business process.

To achieve this, it uses data, statistical analysis, and quality indicators, enabling you to identify the origin of errors, apply solutions, and measure success.

Its goal? Achieve near-perfect quality where each outcome meets the highest standards.

It’s worth noting that although Six Sigma was born in manufacturing, its scope has expanded to many sectors. Today it’s used in financial services, healthcare, technology, and logistics, as it enables evidence-based decision-making.

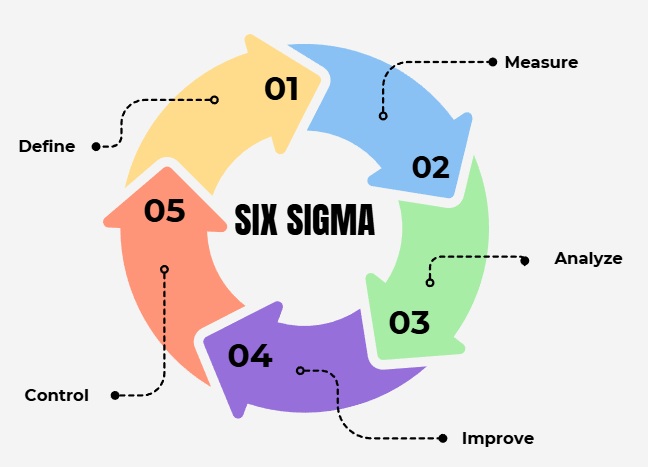

The Six Sigma methodology is based on a cycle known as DMAIC, a model that guides continuous improvement processes.

DMAIC comes from the initials of each stage:

Define. Identify the problem, project objectives, and customer needs.

Measure. Collect relevant data on the current process to establish a baseline.

Analyze. Study the causes that generate errors or variation affecting quality.

Improve. Implement solutions that eliminate the detected causes and optimize results.

Control. Finally, monitor the changes to ensure they’re sustained over time.

On the other hand, Six Sigma has a hierarchical structure that allows responsibilities to be distributed and process consistency to be maintained. These roles play a key part in ensuring each stage of the DMAIC cycle is executed correctly.

Six Sigma includes different levels of specialization to ensure proper application within organizations.

Each plays a specific role:

White Belt. Introductory level covering basic concepts and a support role on improvement projects.

Yellow Belt. Understanding of the DMAIC phases, participation on improvement teams, and support for process analysis.

Green Belt. Intermediate level, with deeper use of statistical tools and project management to lead improvements within a specific area.

Black Belt. Focused on directing complex projects, supervising multidisciplinary teams, and the strategic application of the methodology.

Master Black Belt. Mastery level of Six Sigma, focused on strategy design and leader development.

How to obtain these certifications?

Through academic institutions, quality organizations, and professional training centers recognized internationally, for example:

American Society for Quality (ASQ): Six Sigma Certifications.

International Association for Six Sigma Certification (IASSC): Lean Six Sigma Certification – Globally Recognized.

The certification system validates different levels of mastery over its tools and principles.

What is Lean Six Sigma?

In simple terms, it’s a combined methodology that includes:

Lean Manufacturing: focused on eliminating waste and increasing efficiency.

Six Sigma: focused on reducing process variability and errors.

Although both aim to streamline processes, they differ in how they achieve it:

Lean: centers on speed, efficiency, and customer value.

Six Sigma: focuses on quality, consistency, and data-driven decisions.

By integrating this combination, you get faster processes with fewer errors.

For example, if you run an e-commerce business, you can apply Lean to reduce order prep and shipping times, and use Six Sigma to decrease errors in packaging or invoicing.

Adopting the Six Sigma methodology provides tangible operational, financial, and people-related benefits.

Key benefits include:

Process standardization. Helps document and replicate efficient practices, reducing reliance on external factors or improvisation.

Quality improvement. Products and services become more consistent and reliable by reducing process variation.

Cost reduction. Failures, rework, and waste are eliminated, generating significant savings for the company and facilitating the achievement of financial goals.

Greater customer satisfaction. Error-free, more efficient service strengthens trust and loyalty toward the brand.

Culture of continuous improvement. Encourages active staff participation in identifying and solving problems, driving an innovative environment.

Six Sigma principles, at a strategic level, align with the philosophy of deep work, promoting total focus and excellence in results.

A real case is Bank of America, which adopted the Six Sigma methodology at the corporate level in 2001. In addition to helping reduce credit approval times, it improved customer satisfaction.

DMAIC phase | Action at Bank of America |

Define | Set the objective of improving customer satisfaction and reducing defects in banking services. |

Measure | Collected data on response times, errors, and rates of “not delighted” customers. |

Analyze | Found that many processes were duplicated and manual validations generated errors. |

Improve | Implemented automation, Six Sigma training, and flow redesign with control tools. |

Control | Established quality indicators and business goals linked to Six Sigma staff training. |

As mentioned, Six Sigma was born in industrial settings, but its principles can be easily adapted to different contexts.

Here are the steps to follow:

Select a key process. Prioritize based on customer satisfaction, costs, or delivery time.

Define project objectives. Set clear, measurable goals aligned with the company’s overall strategy.

Identify quality indicators. Measure cycle times, error rate, or customer satisfaction level.

Collect reliable data. Record results and establish a baseline.

Analyze root causes. Use graphic organizers to visualize causes and prioritize the factors generating errors (e.g., Pareto or Ishikawa diagrams).

Implement improvements. Design feasible solutions and plan a realistic execution schedule.

Control and standardize. Create monitoring dashboards and audits to maintain continuous improvement processes.

Leverage collaborative tools. Options like Google Workspace integrate functions to document processes, monitor results, and coordinate improvement teams.

Applying the DMAIC cycle doesn’t require large structures—just consistency and analysis.

Six Sigma is a methodology that transforms how you work by focusing on precision, quality, and constant analysis. In doing so, it helps build stronger, more efficient organizations centered on real customer value.

Its disciplined structure reduces errors, optimizes resources, and keeps processes stable over the long term. It also drives data-based decisions and operational efficiency.

Now, if you’re looking to optimize your finances so every move is more efficient, use DolarApp.

We’re your ally for receiving and sending digital dollars or euros (USDc/EURc). Just download the app and activate your account to start making international transactions. You can also convert currencies with a fair exchange rate.

DolarApp charges a small standard fee of 3 USDc/EURc per transaction.

It’s a management strategy that combines statistical analysis and operational discipline to reduce errors and optimize process performance. Its purpose is to achieve maximum efficiency and operational quality.

Lean focuses on eliminating waste and optimizing flow, while Six Sigma seeks to reduce variability and defects through statistical analysis. Combined, they enhance efficiency and quality.

Companies like Motorola, Bank of America, General Electric, Amazon, and 3M have applied Six Sigma—to improve processes, reduce costs, and increase customer satisfaction across sectors.

It enables better internal management, reduces waste, and improves result consistency. It also strengthens decision-making, customer satisfaction, and business profitability.

Sources:

Independent third-party Lean Six Sigma certification

Os países têm fronteiras. Suas finanças, não mais.

Freelancer tips

Freelancer tips O diagrama de fluxo de processos ajuda a organizar tarefas, aumentar a produtividade e apoiar uma tomada de decisão mais eficiente. Saiba como criar um aqui.

Freelancer tips

Freelancer tips A business brings new challenges and decisions as it scales. Learn the stages of business growth and identify which stage you’re in.

Freelancer tips

Freelancer tips A well-written privacy policy makes users trust your site more. Here are the necessary elements and a practical example to create one.